The advantages of NOEplast formliners

Third dimension: PU makes things possible

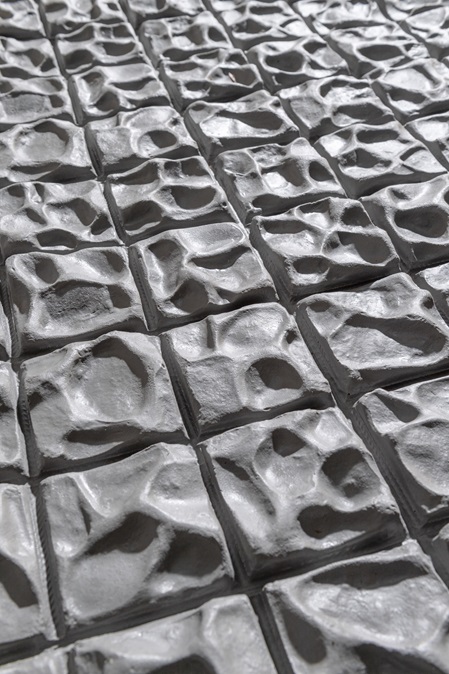

NOEplast formliners are made of PU Elastomer. Inserted into concrete formwork, they shape and form concrete surfaces, giving them a third dimension.

NOEplast formliners exploit the versatile characteristics of elastomer resins to precisely reproduce the fine grain detail of wood and the striking appearance of stone. The resins‘ elastic and robust properties allow precise creation of tight radius curves.

Direct benefits:

- Faithful reproduction of details

- Longevity and resistance to external influences

- High elasticity allows flexible adaptation to different shapes and surfaces

Efficient and time-saving: Pre-assembly on plywood

The formliner is fixed directly to the formwork or other supporting sheets, saving time and money.

Work is coordinated in accordance with the schedule drawn up beforehand (or in advance), which makes for fast, efficient installation. On site, fixing the formliner to a plywood sheet or to the formwork is sometimes difficult. This is particularly true when weather conditions are unfavorable, or the substrate is uneven.

NOE offers an optional special service to solve this problem. The formliner is bonded directly to a plywood sheet or to the formwork. Ready-to-use preassembled elements are delivered directly to the site (in-situ) or to precast plants and can be used immediately.

Direct benefits:

- Direct application to formwork

- Time-saving, as time-consuming fixing and assembly steps are eliminated

- Unfavorable site conditions such as lack of space and bad weather are avoided

- The crane‘s capacity is not blocked

- Immediate use, without additional assembly work

- Support from the formwork and formliner expert

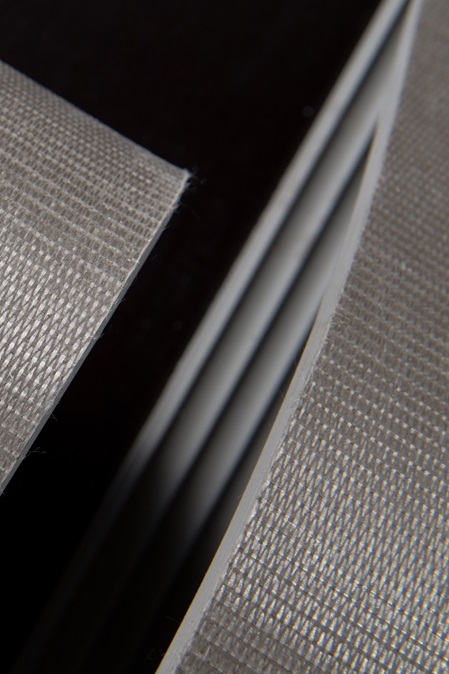

Stable and robust: The fibre-reinforced back

NOEplast formliners are characterized by their back reinforcement with a fibre mesh.

High dimensional stability is essential for the efficient use of formliners. That is why NOE formliners have a fibre fabric on the back. This not only ensures form stability, but also improves tear resistance. No formliner sanding is required before gluing the formliners, which saves a lot of time. The formliners can withstand temperatures of up to +80°C.

The optimal combination of material and fabric of the fibre backing means that NOEplast formliners can be used up to 100 times. This feature makes them easy to use, while guaranteeing high levels of reusability.

Direct benefits:

- Long-term use and resistance

- Ease of application

- Time saving

- Guaranteed high number of uses

Beautiful functionality for a wide range of applications

NOEplast formliners can be used in a wide range of applications. As well as facades and bridges, they are also used to meet challenges such as antislip floorings or noise protection. This makes them not only pleasing to the eye, but also functional.

NOEplast‘s versatile formliners are used in a wide range of applications, and are particularly well suited to specific challenges such as noise protection or floor tiles. Thanks to their aesthetic design and functional properties, they help to improve appearance and meet important functional requirements in a variety of environments.

Direct benefits:

- Can be used in a wide range of applications

- Designs blend into the landscape

- Customisable to individual specifications and wishes

- Additional benefits include anti-slip properties and noise protection