Wall formwork with profiling

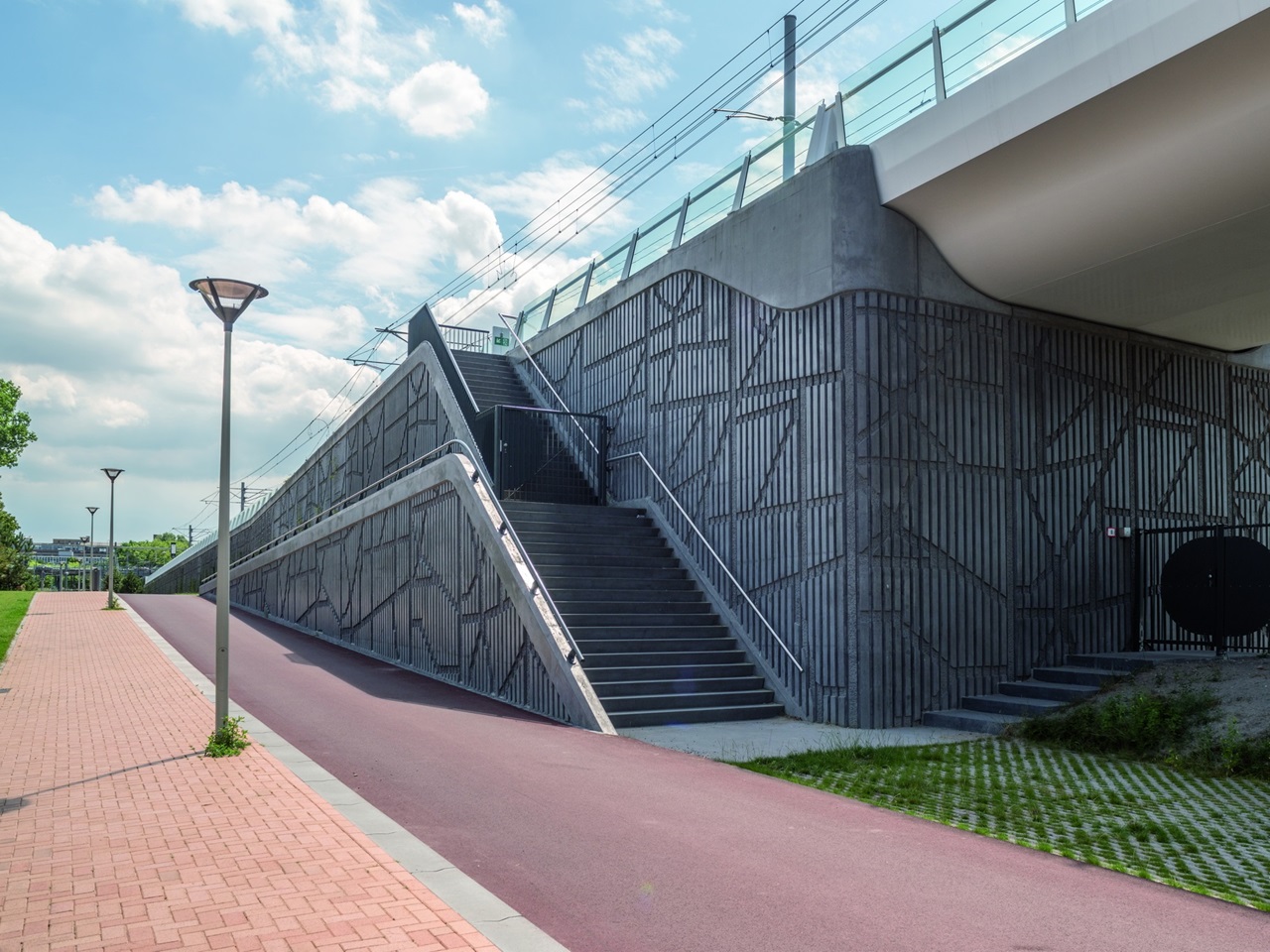

For the Erasmus line, a fast light rail connection between Rotterdam and The Hague, BAM Infra Projecten realized a new starting station based on a design by Zwarts & Jansma Architects. A remarkable detail of the underlying concrete container construction is the floor plans of Den Haag, which are embedded in the concrete wall. NOE-Betonvormgeving developed a solution to integrate the street pattern during the concrete casting.

Street pattern

The settlement-free slab consists of a U-shaped, founded concrete container construction. At the end of it is the abutment, to which the steel viaduct connects. The concrete container construction is realized in six sections. After completion, the concrete container is filled with sand, on which the railway track is built. A remarkable detail of the concrete walls of the container construction is the surface design chosen by the architect: a street pattern that is cast into the concrete. The city plan is the result of a study conducted by Zwarts & Jansma Architects based on the current city plans of Den Haag. Pieces were cut out and assembled into a specific pattern. The pattern is a patchwork of fragments from the various districts of Den Haag. To create the pattern, the districts were sometimes made a bit more abstract by omitting small streets. To implement the street pattern, NOE-Betonvormgeving developed an execution methodology with design and detailed planning.

Clever combination

For clear visual recognition, the pattern lies up to 60 mm deep in the concrete. To achieve this depth, profiling with the well-known NOEplast textured formliners is a costly solution. Therefore, a combined approach was proposed: The construction company applied a sheet pile-like profiling made of conically planed and painted wooden beams to the formwork. In between, the robustly profiled, 30 mm deep street pattern was installed. These were made by NOE-Betonvormgeving from CNC-milled NOE model building panels with the Bayreuth design. The surface of the model building panel was equipped with the NOEplast textured formliner type Bayreuth.

The model building panel developed by NOE offers a number of essential advantages. The panel can be easily processed by sawing, milling, etc., which gives architects and builders great design freedom. Additionally, it is noteworthy that the panel can be provided with a profiled surface. The material can be used as formwork material without further surface treatment under the same warranty conditions as the NOEplast textured formliners. This means that the material is guaranteed to be reusable 80 to 100 times.

Efficient implementation

The concrete container construction is realized with two large, 25-meter-long wall formworks with three repeating pattern areas. One of the formworks has a height of 7.85 meters, the other 5 meters. For applying the profiling on the formwork, a total of about 2,100 loose profile blocks and strips were manufactured. For efficient assembly and effective processing, NOE-Betonvormgeving created an assembly plan. With CNC-milled template plates, the contractor was able to mark the entire structured surface on the base formwork. This way, the painted wooden beams could be mounted precisely in the correct position. Using a numbered overview drawing, the numbered profile blocks could then be screwed in between.