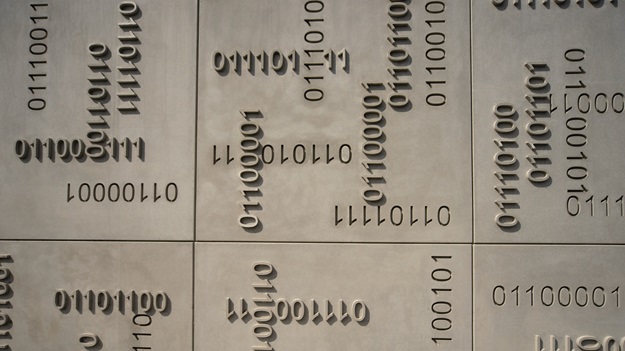

Facade with binary code

In Belgium, a data centre is being built. Its geometry is very plain – in one sense, it is a use-oriented, flat-roofed building with very few openings. And yet, the designers have made it into a real eye-catcher: they have covered the concrete facade with binary codes, which make reference to the building's use.

The quantity of digital data is continuously increasing. As a result, there is a demand for buildings to store and process all this data securely. Two companies, Atos, a Belgian IT service provider, and Syntago, a subsidiary of NMBS, the Belgian national rail company, are building the Alpha Cloud computer centre in Belgium. The works are taking place in Mechelen, between Brussels and Antwerp. The computer centre is notable for its state-of-the-art technology. For example, a well-designed power supply system ensures that the main computer is always supplied with electricity and continuously cooled.

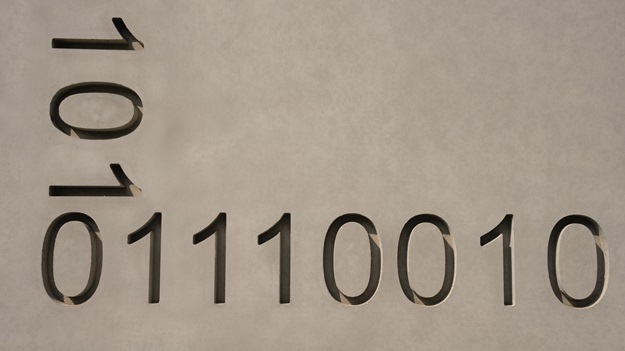

Binary code in the facade

But the building is not only technically outstanding on the inside, it is a real attention grabber architecturally too: its concrete facade is covered with eight-digit binary codes made up of the numerals zero and one. This binary code is an allusion to the function of the building. It was made possible by the use of NOEplast textured formliners. The NOE-Schaltechnik engineers used a CNC milling machine to transfer the customer's motifs onto supporting boards, which formed the basis for the manufacture of the textured formliners. Special aspect: normally the designers choose textures in which the motif is either recessed into the concrete surface or projects out of it. In this case, the designers included both effects and thus gave the facade a special sculptural appearance.

Multiple uses – save money

In order to build the computer centre as quickly as possible, the site management opted to use precast concrete units. The facade panels were subsequently manufactured in the precast concrete works as composite elements. Although each of the eleven formliners had dimensions of only 1.41 x 1.41 m – almost two square metres in area – multiple uses made it possible to manufacture all the concrete panels necessary for cladding the 2700 m² facade surface from them.

NOEplast textured formliners can be reused up to 100 times! The precasting works team realised that by assembling modules of three of the square standard textured formliners, they could work in the most efficient way by concreting a 4.23 m width x 1.41 m high panel in one pour. This saved time not only on the concreting but also on the erection, which contributed to building the computer centre in less than twelve weeks.